Intro to Honeycomb Panels and Uses

What are Honeycomb Panels?

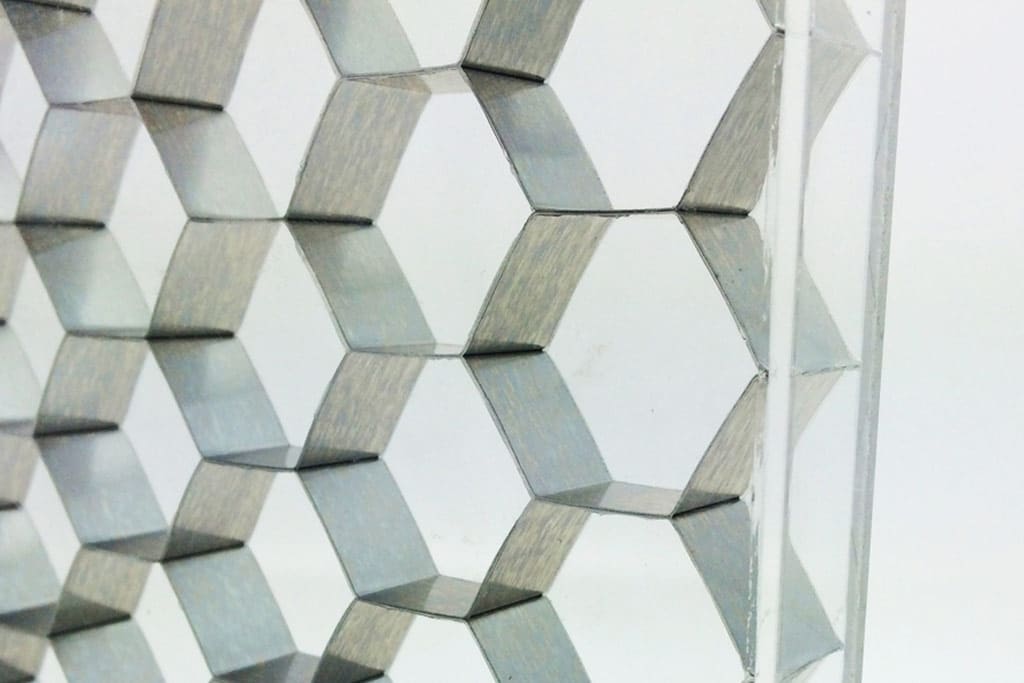

Honeycomb panels are sturdy and lightweight building materials often used in the exterior cladding market. The panels get their name from its hexagonal interior that is similar to honeycombs. Honeycomb panels have a core composed of hollow cells sandwiched between two thin faces to create an air space between the faces. These cells are usually hexagonal or arranged in columns. Honeycomb panels are used for flat or curved panels depending on how the panels are used and the high specific strength needed for the panels.

Advantages of Different Honeycomb Panel Materials

Honeycomb panels can be made from different materials, such as porcelain or stone on the surface or cosmetic face. There are several advantages of honeycomb panels, but the primary benefit is the panels’ strength.

Hexagonal shapes in nature, such as honeycombs, create structures that distribute force evenly, making the structures of the hexagonal shape mutually supportive. With these mutually supportive inner structures, honeycomb panels can withstand high winds and shocks such as earthquakes. Other benefits of honeycomb panels are the panels can pack more structure cells in a space because of the hexagonal shapes. The panels are lightweight because they need fewer materials but have more area. Thus, the panels are easy to transport and have easy installation.

Honeycomb panels are the economically-savvy choice because the lighter weight of the panels also enables the user to reduce packaging and shipping costs significantly.

Honeycomb panels are commonly found in many materials:

Aluminum Honeycombs

Aluminum honeycomb panels have a high strength to weight ratio. These panels have a mixture of cell shapes that are geometrically paired with foil thickness and cell size. As honeycomb panels, the aluminum materials are in block forms that are not expanded and stretched to form sheets. The benefits of aluminum honeycomb panels are they are strong and flexible. Aluminum honeycomb panels are corrosion resistant, have elevated temperature performance, and are fire-resistant. These panels will not absorb moisture and therefore are fungus resistant. Aluminum honeycomb panels can be easily machined and formed.

Nomex Honeycombs

Nomex honeycombs are created from Nomex paper. This is a type of paper created from meta-aramid papers infused with thermosetting phenolic resin. The Nomex honeycomb panels have advanced strength with fire-resistant properties. These panels are often used in aircraft interior panels. The Nomex panels have low density, solid stability, and mechanical strength. They have a high strength to weight ratio, are easy and flexible to process corrosion resistance, and have good thermal insulation. They are useful for being formable into 3-D shapes.

Kevlar Honeycomb Core

These honeycomb panels are based on Kevlar and are manufactured by infusing Para-aramid papers with heat-resistant phenolic resins. An advantage of Kevlar is that it is stronger than Nomex, having improved resistance to material fatigue and abrasion. The material is a good insulator for electricity and heat and improves corrosion resistance.

Thermoplastic Honeycombs

Thermoplastic honeycomb panels are lightweight and easy to recycle. These panels come in several types and varying properties depending on the type. Some varieties of thermoplastic honeycomb panels are:

- Acrylonitrile Butadiene Styrene (ABS) offers a rigid structure. It is a tough material with good surface hardness and impact resistance. This thermoplastic material has dimensional stability, can be melted down, and is recyclable into other products.

- Polycarbonate (PC) plastics are transparent thermoplastics. The material permits light to transmit in almost the same way as glass with UV stability. Polycarbonates are good for impact resistance and/or transparency. These materials can give good heat resistance and self-extinguishing properties, especially if combined with flame retardant materials.

- Polypropylene has several advantages as a honeycomb panel material. It has good chemical resistance to diluted bases and acids. The material has elasticity and toughness, deforming without breaking. It has plasticity and is flexible. The material has good insulation with high resistance to electricity.

- Polyethylene can offer electric insulation offering, can be almost transparent to opaque, and can be recyclable into other products. It has heat-resistant properties.

Stainless Steel Honeycombs

Stainless steel honeycombs are some of the strongest honeycomb panels available on the market, ideal for extreme environments and striking facades.

Disadvantages of Honeycomb Panel Materials

The disadvantages of honeycomb panels depend on the material, including:

Aluminum Honeycomb Panels

While corrosion-resistant, aluminum honeycomb panels should be used with caution if near salt-water environments. Salt-water environments can corrode aluminum honeycomb panels. These panels should be used carefully near carbon skins. Carbon skins can cause galvanic corrosion to aluminum honeycomb panels with conductivity aggravating this problem. Aluminum honeycomb panels also have no ‘mechanical memory.’ If a cored laminate impacts an aluminum honeycomb, the panels will deform irreversibly. The result is an area with reduced mechanical properties.

Nomex and Kevlar Honeycomb Core Panels

While Nomex and Kevlar are made from strong and fire-resistant materials, these panels tend to be expensive.

Thermoplastic Honeycomb Panels

Thermoplastic honeycomb panels have difficulty with maintaining a good interface bond between the honeycomb and the panel skin. This can lead to degradation of the building cladding or other structures.

Stainless Steel Honeycombs

While stainless steel honeycombs are ideal for extreme conditions, stainless steel still is not completely corrosion resistant in salt-water environments, and can be heavier than most other types of materials like aluminum.

How to Use Honeycomb Panels

Many different industries use honeycomb panels even outside of construction such as aviation and transportation. For example, honeycomb structures are used for aircraft wings, train bulkheads, and floors, the exteriors of cars, and car doors.

Honeycomb shapes are used extensively for construction such as the exterior cladding of buildings, but honeycomb panels can also offer structural strength to other building areas. Curtain walls, louvers, and roofs for buildings are other places honeycomb panels are found in addition to exterior facades.

Interior decoration uses honeycomb panels as screen dividers and soundproof panels. Due to its lightweight nature, honeycomb panels are incorporated into mobile homes or other structures that are temporary or extra buildings, (“portables”) for schools, churches, and other organizations.

Learn more about Monarch Metal’s hanging systems for hanging systems for honeycomb panels and deform nuts today.