A Sticky Solution for Cladding Installation

Adhesive cladding systems have become increasingly popular in construction due to their many advantages over traditional mechanical fasteners. These systems are used to attach cladding in a variety of applications, especially where thinner, lighter materials are used. These can include metal panels, fiber cement, high-pressure laminates (HPL), glass, and even some thin stone.

Adhesive technologies have advanced well beyond what has been available in the past, and should be seriously considered for cladding attachment. In this article, we will discuss why adhesive cladding systems have advantages over some typical cladding systems.

Fastener-Free Appearance:

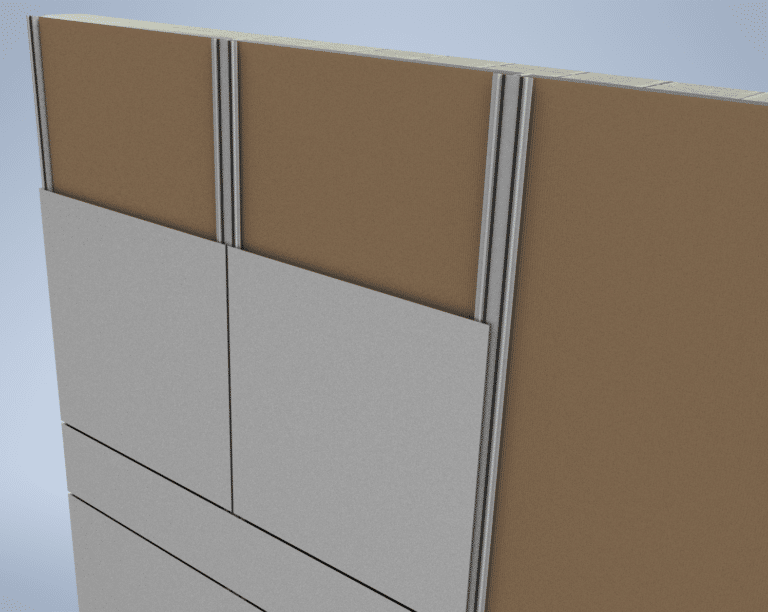

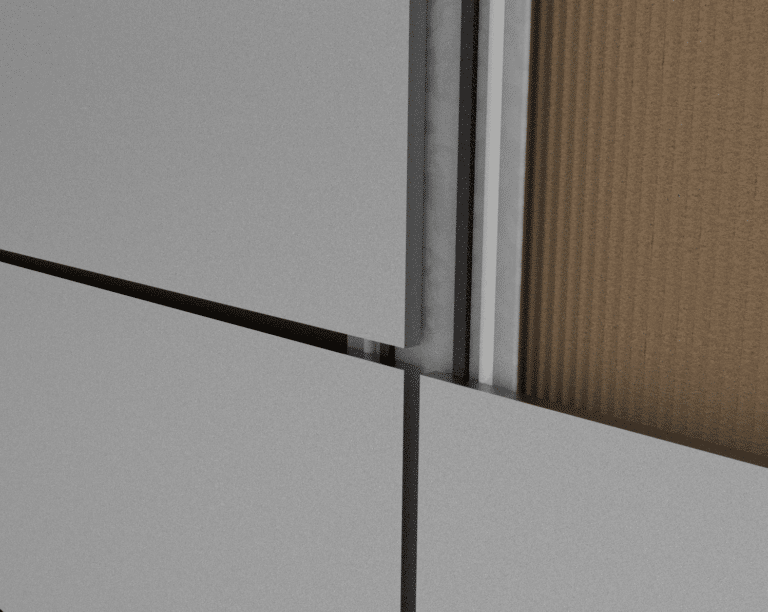

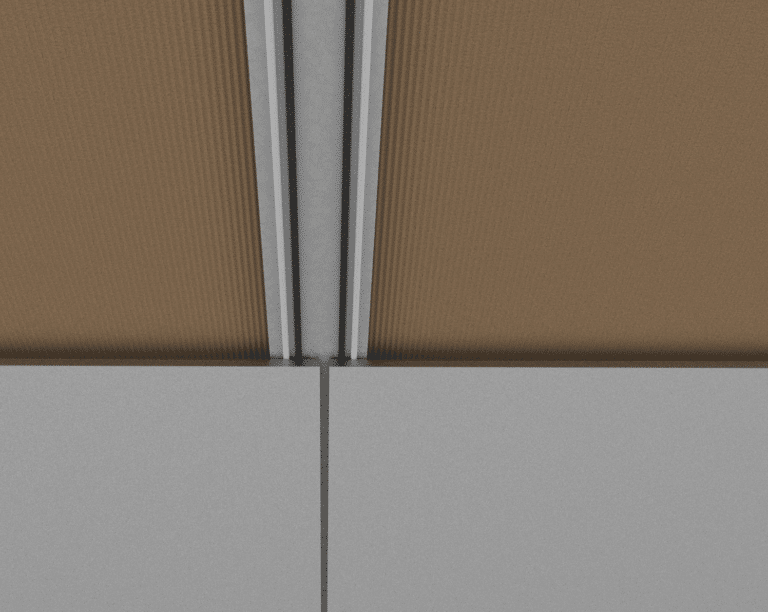

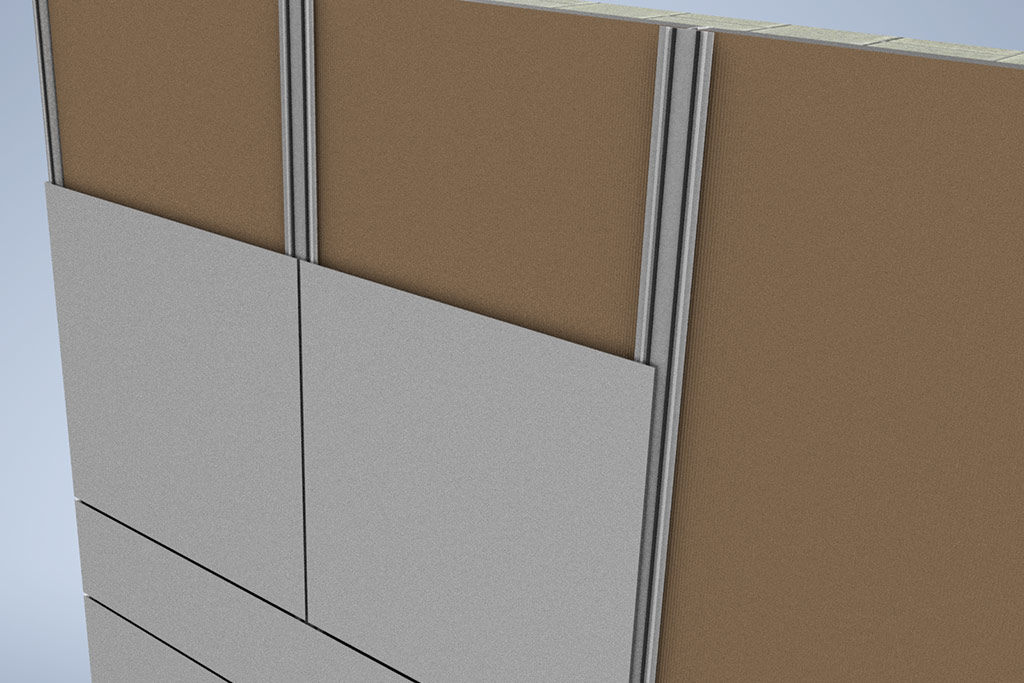

Hidden fastener systems are incredibly popular for both exterior and interior cladding, and provide a clean, smooth appearance. They can also add some security to the installation since fasteners are not readily accessible. While hidden fastener systems are a great solution for thicker panel and heavier products, thinner cladding can struggle to accommodate the anchors required for installation. This typically results in an exposed fastener system.

Adhesive cladding systems eliminate the need for visible mechanical fasteners, resulting in a cleaner and more uniform appearance. The smooth surface creates a sleek and modern look that enhances the overall aesthetic of the building. This also eliminates the need to drill holes in the panels, which can act as stress risers in brittle panels like porcelain.

Faster Installation:

Adhesive cladding systems can be installed more quickly than mechanical fasteners. This is because the adhesive can be applied quickly and easily, without the need for drilling holes and inserting fasteners. Most systems are installed with a foam double-sided tape, and an adhesive. The foam tape provides the initial tack while the adhesive cures. In a well designed system, the installation time decreases significantly, which decreases total labor costs. The required skill to install the panels is also decreased by using adhesives.

Improved Durability:

Adhesive cladding systems can also provide improved durability compared to mechanical fasteners. This is because the adhesive creates a strong and secure bond that can withstand the stresses of expansion and contraction caused by temperature fluctuations. The foam tape and adhesive both have degrees of flexibility that fasteners just can’t match.

Increased Thermal Performance:

Adhesive cladding systems can help to improve the thermal performance of the cladding substructure by reducing the amount of conductive material. In a typical commercial installation with continuous insulation, a clip and rail concealed fastener system must be installed over furring z-girts, wall brackets, etc. In an adhesive system, the furring is still present, but the cladding can be installed directly onto the furring.

Reduced Noise Transmission:

Adhesive cladding systems can also help to reduce noise transmission from the exterior to the interior of the building. The adhesive and tape creates a continuous layer that increases the sound transmission coefficient for the entire system.

Reduced Maintenance:

Adhesive cladding systems require less maintenance than mechanical fasteners. This is because the adhesive creates a strong and durable bond that does not require tightening or replacement. Fasteners should be inspected for corrosion, and in some cases with exposed fasteners, UV degradation of rubber washers. These washers are used to provide a galvanic break between the fastener and panel, and when the washer breaks down, can result in corrosion or panel failure.

The adhesive and tape are both protected from UV exposure after installation, and won’t suffer from the same degradation.

Increased Design Flexibility:

Adhesive cladding systems offer increased design flexibility compared to mechanical fasteners. This is because the adhesive can be used to attach cladding materials to a variety of substrates, including concrete, masonry, metals, and even wood. Typical cladding support systems can become highly complicated to detail, and costly to install when accommodating unique designs. Adhesive systems can avoid some of those complications, since placement doesn’t rely on perfect fastener placement.

In conclusion, adhesive cladding systems can offer many advantages over traditional mechanical fasteners. As a result, these systems are becoming increasingly popular in construction and are likely to continue to grow in popularity in the coming years. Here at Monarch we’re happy to offer up a variety of compatible support systems for adhesive use, reach out to us to learn more about these systems, and how we can help you embrace adhesive cladding systems.